Microalgae between potential and reality

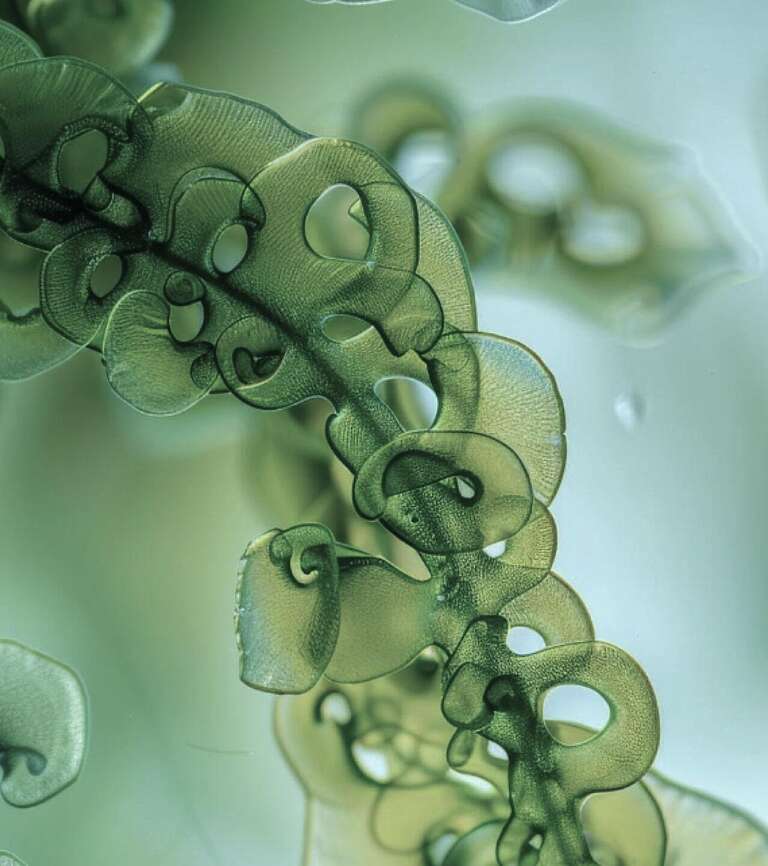

Microalgae offer an exceptionally wide range of applications—from functional ingredients for foodstuffs to high-quality cosmetic active ingredients and pharmaceutical applications. Their biological potential has been scientifically proven for years, but their industrial use often falls short of expectations.

One key reason for this lies in the manufacturing process itself: many existing production methods are based on open systems that are highly dependent on external influences. Fluctuating environmental conditions, contamination by pollutants or heavy metals, and a lack of process control lead to inconsistent quality and significantly limit the possible uses of algae.

However, reproducible purity, consistent ingredients, and reliable supply chains are crucial, especially for regulated and quality-sensitive markets such as food and cosmetics. This makes it clear that the potential of microalgae can only be fully exploited if their production is technologically controllable, scalable, and suitable for industrial use—which is what Algene achieves.

Algene makes purity scalable.

A new generation of microalgae production

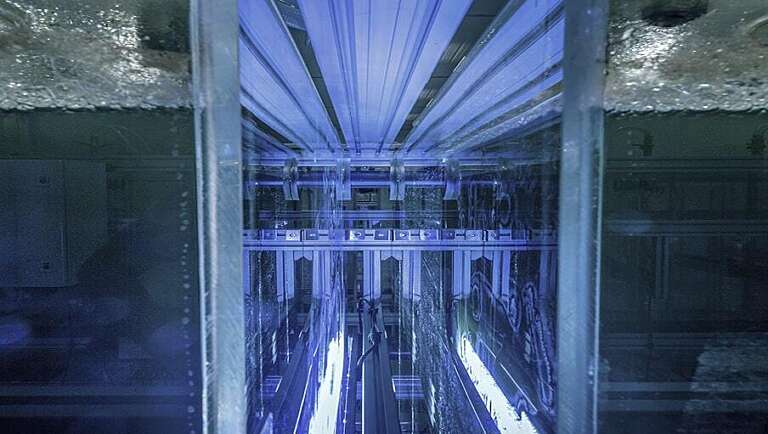

Algene International AG develops and operates a highly innovative, partially patented technology for the controlled cultivation of microalgae. Unlike conventional methods, the algae are cultivated in a closed clean room system under optimal, fully controllable conditions. These include precise lighting, controlled nutrient supply, and the consistent exclusion of pollutants and heavy metals.

The result is microalgae of consistently high quality that grow faster and more efficiently than with conventional production methods. This makes them particularly suitable for demanding applications in the food and cosmetics industries.

Quality as an industrial standard

Controlled clean room cultivation

Closed production systems enable maximum control over growing conditions and guarantee consistent purity and quality.

High-quality applications

The microalgae obtained are suitable as a functional ingredient in foodstuffs and in cosmetic and skincare products with high quality requirements.

Algene's contribution to SDG 17 Goals.

Algene acts as an interface between research, industry, and sustainable biotechnology in line with Sustainable Development Goal (SDG) 17 – Partnerships for the Goals. Close cooperation with scientific partners – including the Technical University of Munich – forms the basis for continuous development and quality assurance.

Through scalable, resource-efficient production processes, Algene makes concrete contributions to SDG 9 (Industry, Innovation and Infrastructure) and SDG 12 (Sustainable Consumption and Production). Controlled manufacturing reduces environmental impact and enables reliable supply chains for high-quality applications.

At the same time, Algene supports decent work and economic growth (SDG 8) by building technology-based value creation. Responsible use of natural resources also contributes to SDG 13 (Climate Action) and SDG 6 (Clean Water and Sanitation) along the production chain.